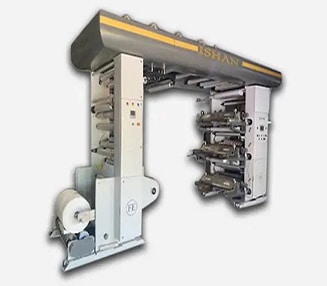

Rotogravure Printing Machine Manufacturer in India

As the famous manufacturer of Rotogravure Printing Machine, Electronic Line Shaft (ELS) Rotogravure Printing Machine, 8 colour Rotogravure Printing press, 6 colour Rotogravure Printing press, 4 colour Rotogravure Printing making line, 2 colour Rotogravure Printing production machine supplier in Gujarat, India

We offer ideal quality the stack sort of 8 shading rotogravure printing machine. Our shaft-type-slitter-rewinder-machines are utilized to naturally control a wide range of adaptable materials. The scope of rotogravure printing machines isn’t finished without cover covering machine. It offers better quality multi-layered overlays.

Among the few flexo printing press producers, Ishan International is one of the principle makers in India. In case you are an imprint printing association, by then it is basic to place assets into the right equipment to make magnificent striking names obliging all the necessities of your customers. You can build up your business with the right mix of stuff and programming.

We are a major Manufacturer, Exporter, and Supplier of Rotogravure Printing Machine with heavy-duty material for various industries. We also manufacture Web Guiding Systems for various machineries. We are one of the leading Rotogravure Printing Machine manufacturers in Ahmedabad, Gujarat, India.

Rotogravure Printing Machine Specifications

| Web width | 100 to 1500 MM |

| Max. Weight of Unwind | 100 to 1000 KG (Different models for different weight) |

| Max. Parent Reel Dia. | 400 MM |

| Max. Rewind Reel Dia. | 400 MM |

| Rewind Core Dia. | 76 MM |

| Motor | 2 HP AC / DC Motor (3, 5 HP also available on suitable model) |

| Maximum Designed Speed | 100 to 150 Mtrs / Min |

Our Products

Exclusive range we offers rotogravure machine, Rotogravure printing machine Manufacturer, Supplier & Exporter in India

Doctor Blade Chamber System Flexo

Doctor blades and chambers : Manufacturers in Kalol, Ahmedabad

The most recent development in the flexographic inking process is chamber Doctor Blade Chamber System Flexo. Two doctor blades are used along with an enclosed chamber to dispense the ink to the anilox roll. An anilox roll is a hard cylinder, usually constructed of a steel or aluminum core which is coated by an industrial ceramic whose surface is engraved with millions of very fine dimples, known as anilox cells. For color consistency and job repeatability, delivering and metering ink to the anilox roller needs to be done correctly. If it is, the system can realize the true volume of the anilox roller, by Michal Lodej.Doctoring Rewinding Machine Manufacturer

We have been manufacturing various types of Doctoring Rewinding Machines for different industries and for different applications for client’s perusal. For example Standard Doctoring Rewinding Machine, CI Flexo Printing Machine, Exporter of CI Flexo Printing Machine, Doctor Blade Chamber System Flexo, Doctoring Rewinding Machine Manufacturer, Ceramic Anilox Roller, Closed Doctor Blade Chamber, Blown Film Extrusion Machine, Doctor Blade Chamber System Flexo, Doctor Blade Chamber System Flexo, Doctoring Rewinding Machine Manufacturer, Ceramic Anilox Roller with cantilever design balancing body for easy loading and unloading of parent / rewound reel.

Ceramic Anilox Roller

The ceramic Anilox roller base material adopts special quenching and tempering treatment to ensure its processing and use accuracy has the surface coating of micro concave roll is processed by imported powder and spraying equipment. It has high precision grinding machine ensures high precision requirements of ceramic Anilox Roller. Adopting the world advanced laser carving technology to ensure the smoothness of its mesh structure.

Blown Film Extrusion Machine

Blown film extrusion is a technology that is the most common method to make plastics, films, especially for the packaging industry. The process involves extruding a tube of molten polymer through a die and inflating to several times its initial diameter to form a thin film bubble. This bubble is then collapsed and used as a lay-flat film or can be made into bags. Usually polyethylene is used with this process, and other materials can be used as blends with these polymer.

Closed Doctor Blade Chamber

There are two doctor blades are used along with an enclosed chamber to dispense the ink to the anilox roll where the ink is delivered through a closed loop from the ink pump to the doctor blade system and then back to the pump.

Doctor blade chamber alignment is critical for good closed doctor blade chamber performance. It takes a few minutes to make sure that there is proper system alignment to prevent early and excessive doctor blade and anilox wear, ink leaks, waste and downtime.

Where is Rotogravure Printing can be used?

Rotogravure printing machine is widely used to print newspaper supplements, catalogues, illustrated magazines and books, advertising, calendars, and so on. It is also in use for printing labels and wrappers on cellophane and similar materials.

What is the Difference between Rotogravure Printing Machine and Flexo Printing Machine?

Flexographic printings achieve an edge for short-run occupations while rotogravure printing is favored for longer runs. Printing-press cost works out to be a little higher in rotogravure printing when contrasted with flexographic printing.

What is Flexo Printing Machine?

Flexo printing machine has a high speed printing process and construct use of fast-drying inks. The inked plates have a lift up image and rotate at high speeds to transfer the ink throughout small holes from the anilox roll to the under layer; each color requires a different printing plate.

What is the process of rotogravure printing?

Rotogravure is a type of intaglio printing procedure, which engages engraving the image onto an image carrier. In gravure printing, the image is fixed onto a cylinder because, like offset printing and flexography, it uses a rotary printing press.